Palm shell dryer carbonization process charcoal plant

One of the main applications of palm shell carbonization equipment technology is energy utilization. Palm shell charcoal has the advantages of high calorific value, low ash content, and low volatility.

Palm shell

Palm shell charcoal

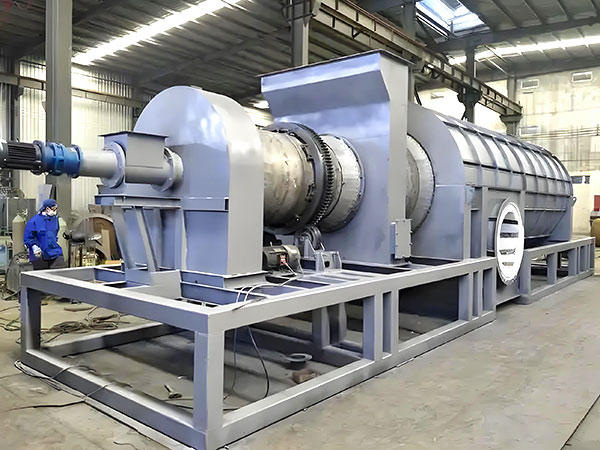

The palm shell carbonization equipment process includes pretreatment, drying, carbonization and cooling process steps. The equipment includes: crusher, raw material bin, belt conveyor, three-channels dryer , screw conveyor, carbonization furnace machine, water-cooled discharging machine, vibrating screen, punching machine and molding equipment, etc.

1. Raw material preparation: selection, cleaning, crushing and screening of raw materials to ensure the purity and quality of raw materials. Put the dried palm shell (containing 6-12% moisture) into the carbonizer and dry the moisture first. Dry at a temperature of 200℃-300℃ to ensure that the moisture is completely volatilized.

Three channels dryer

2. Carbonization process: As the temperature continues to rise, the palm shell enters the dry distillation carbonization process. The dry distillation temperature is 600 degrees Celsius and the time is 40-60 minutes. After dry distillation, palm shells leave fixed carbon. The carbonization temperature should be guaranteed to be above 600 degrees Celsius. The higher the temperature, the shorter the carbonization time.

3. Carbonization furnace preheating: Use liquefied gas to ignite the carbonization furnace, slowly ignite the liquefied gas nozzles in turn, open the valve at the fan outlet, and wait for a large amount of gas to be generated in the carbonization furnace, and the temperature is about 200℃.

Activated carbon carbonization furnace machine

4. Carbonization operation: The dried palm shell raw material is sent into the carbonization furnace through a screw conveyor, and after the preheating and drying section, it enters the low-temperature carbonization zone and the high-temperature carbonization zone for carbonization. The carbonization temperature in the high-temperature carbonization zone is controlled to be no less than 500℃, and the carbonization time is controlled to be 15-20 minutes.

5. Product processing: After carbonization, the raw material generates palm shell biochar and combustible gas. The biochar enters the cold conveyor to be cooled to 30-40℃ before being discharged; the combustible gas enters the sprayer to cool down, and then enters the purifier, cooler and tar filter in turn, and is introduced into the high-temperature carbonization zone of the carbonization furnace through the fan for combustion and heat supply. The excess combustible gas enters the hot air furnace for combustion, and the generated high-temperature flue gas is sent to the dryer.

Related:

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email sales@staurk.com, we will reply to you within 24 hours.